Business

- Building:12000 Sqft

- Annealing Capacity:80 Tons/M

- Wire Production Unit:40 Tons/M

- Genset:40 KW

- Power Capacity:112 KW + 50 KW

RG WIRES

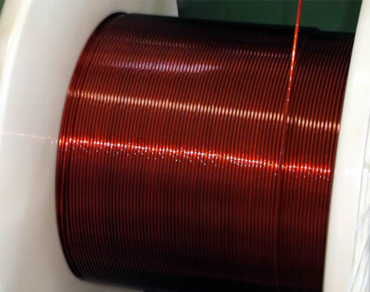

We are happy to introduce ourselves as doing Poly wrap winding wire manufacturing Industry successfully for past 18 years. Our brand name is RG WIRES.

RG WIRES are insulated by thermo plastic materials but not PVC Conductor. Very soft and electrolytic grade annealed bare copper wire from 0.4 mm to 2.00 mm of elongation 40% above are used for working temperature 120 degree Celsius – 150 degree Celsius. High voltage 3kv to 5kv in the water and insulation resistance in better in comparison to PVC wire. It is the only wire which can be used in boiled water and the current leakage is very less.

PUMP COST

RG WIRES have excellent Electrical Mechanical, Thermal and Chemical properties. These wire with stand water abrasion, frictional losses, save space/ size / cost /and work is every type of typical conditions.

TEAR RESISTANT

The structure of insulation is oriented bi-axially propagation of tear is difficult. The multiple 3 layer construction ensures high dielectric quality of insulation places the insulation concentrically around the conductor.

LESS LEAKAGE CURRENT

EASY WINDING

HIGHER LIFE

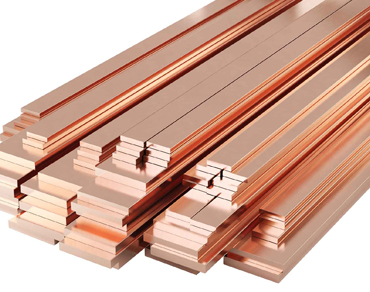

WIRE CONDUCTOR

- The wire conductors will be circular solid as per the specific size of requirement. The wire conductor will be clear bright reasonably uniform in size and shape, smooth and free from spills, cracks and other defects. No joints will be made in finished conductor of wire.

- The quality of the wire is of from Hindalco Industries Ltd Bare Copper, Which is drawn in sizes and annealed according to the temperature.

- The range of size include solid round conductor dia 0.5 mm to 2.0mm.

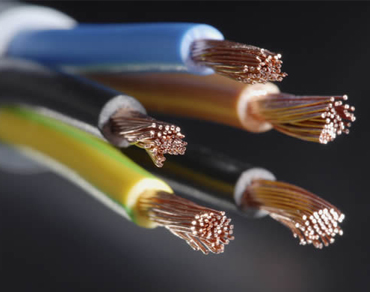

- Polyester / BOPP / Poly Propylene films insulated on wire for maximum rated conductor temperature of 120 degree Celsius to 150 degree Celsius.

- The wire conductor is insulated bi-axially uniform way by BOPP film with latest technology with reference of The Indian Standard IS – 8783 – 1995 Part 4.

PROCESS DEVELOPMENTS

- We make the film Pancakes so that after consuming the entire Pancake we cut the wire and thus there are no joints. Due to joint-less wrapping, chance of water seepage on the bare conductor are eliminated and thus the insulated wire does not fail in High Voltage as well as megger.

- The length of wire can be maintained by use of counter Meters installed on the machine. We can make standard lengths with reasonable tolerance as per customers requirements.

- The reduction in temper is done through proper annealing of bare copper wire at 350 degree Celsius to 400 degree Celsius under inert atmosphere. Also the control of tension of the film during lapping reduces the temper of finished wire.

- Tension of film is checked intermittently during lapping process to have optimum lapping i.e. not very loose or not extra tight. This has resulted in maintaining the temper of wire of easy windability.

FILMS